Optimization within packaging solutions is not just about saving money – it’s about creating sustainable, efficient, and long-term improvements throughout the packaging process.

By identifying key areas for optimization, your company can free up resources, improve quality, and strengthen your competitive edge.

Let us explain the benefits of optimization and explore how you can make it happen.

A successful optimization can offer several concrete advantages:

To succeed with optimization, it’s wise to focus on the areas with the greatest potential for improvement. Here are some of the most important ones:

1. Supplier Optimization

Reducing the number of suppliers can simplify logistics and create better negotiation opportunities. A well-thought-out supplier management strategy can lead to a more streamlined process and lower administrative costs.

2. Packaging Range

Optimizing the packaging range involves reviewing and reducing the number of different packaging types and materials used. This can save significant amounts in both transport and handling costs.

How to Optimize Your Packaging Range:

By optimizing these areas, you can reduce costs and improve the sustainability of your transport processes.

3. Logistics and Warehousing

Efficient logistics are essential for success. Optimization can ensure smoother workflows for both inbound and outbound deliveries. Automated solutions, such as goods labeling and integrated logistics systems, make processes even more efficient.

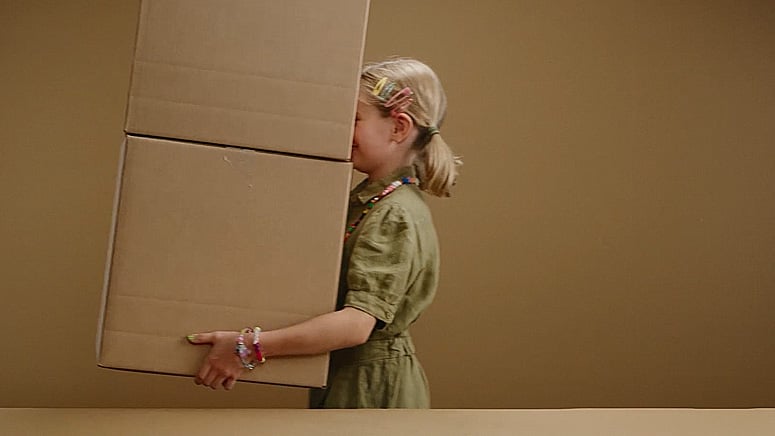

4. Work Environment and Ergonomics

Don’t forget the people in the process. Ergonomically designed packing stations and optimized workflows reduce the risk of strain injuries and create a safer work environment for employees.

Case Elgiganten: We helped Elgiganten optimize their packaging solutions by switching to a single supplier and simplifying and streamlining their packaging range.

Case Alfdex: The case erector helped Alfdex optimize and increase their capacity.

Would you also like to benefit from optimization? Here are three simple steps to get started:

1. Needs Analysis: Map out your current processes and identify potential areas for improvement.

2. Set Goals: Define clear objectives, such as reduced costs or an improved work environment.

3. Implement Gradually: Introduce changes in smaller steps to evaluate and adapt the results.

Optimization is not a one-time effort – it’s a continuous process that develops over time. By identifying and improving key areas, you can create an efficient, sustainable, and profitable packaging process that strengthens your competitive advantage.

Would you like to know more about how Boxon can assist you with optimization Contact us directly for a consultation.